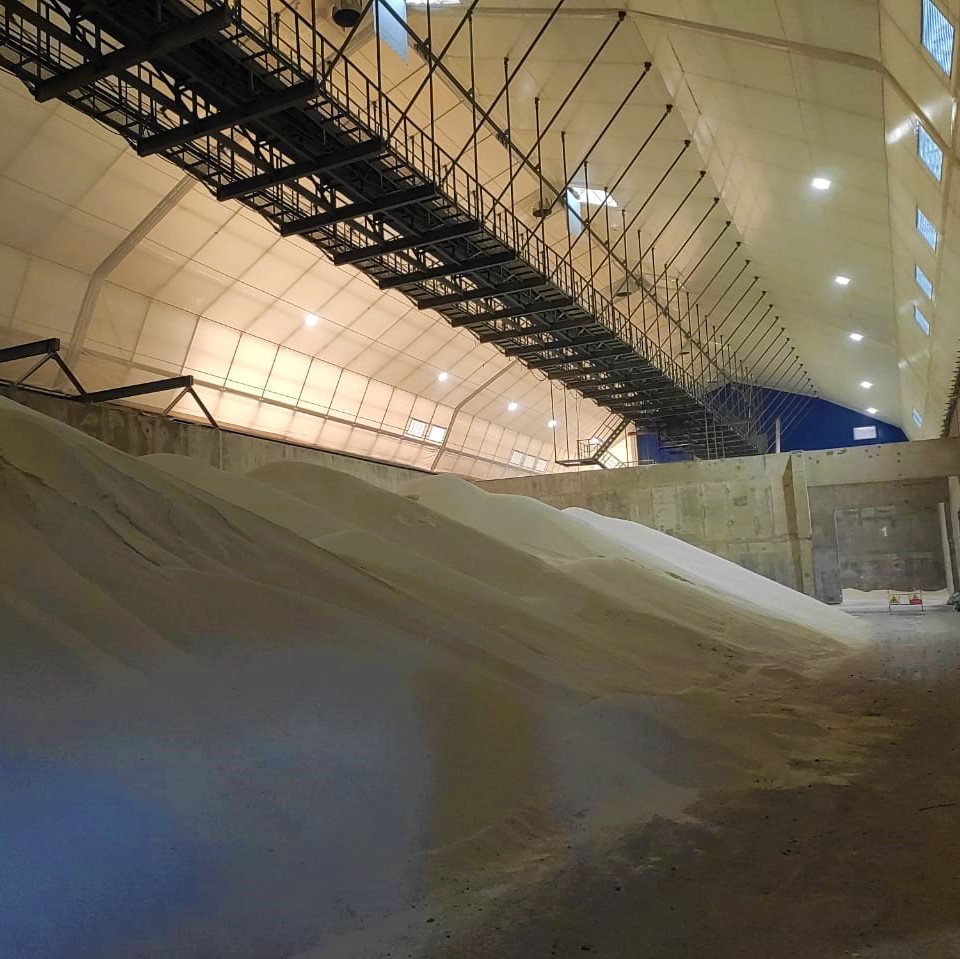

Warehouse for mineral fertilizers with a capacity of 30 thousand tons

Technical and economic characteristics:

Building area: 6543.60 m2

Construction volume: 124,789.66 m3

The total area of the building: 6432,00 m2

Dimensions: 51.20x126.00x27.78 m.

Floors: 1

Storage product: mineral fertilizers

Warehouse type: floor-standing 3-sectioned warehouse with one stationary and one collapsible and easily removable partition; products are placed in bulk

Fire resistance of the building: IV.

Class of constructive fire hazard: C1.

The functional fire hazard class of the building is F5.2.

The building is not heated.

The frame of the building is an arch-type metal structure. The supporting structures are flat steel trusses and columns. Rigidity is provided by struts and braces.

Facades: frame made of polymer-coated steel profiles. There are 6x6 m swing gates with a wicket; gates are located on each end side of the warehouse.

Roof: soft, made of polymeric PVC materials.

Features of the project:

The project used effective solutions for the joint layout of the frame-awning shelter and complex suspended structures of conveyor galleries.

The supply of the product to the new warehouse is carried out from the existing buildings using the new conveyor galleries through the new transfer units, followed by distribution along the entire length of the warehouse using two rolling conveyors on suspensions.

The product is shipped from the warehouse using a diesel bucket loader through loading devices (a device for crushing lumps is provided in the loading device) onto a belt conveyor and through an elevator to a control classification and conditioning unit. For the control classification of the product, the installation of screens is provided. After screening, the substandard fraction is sent to the receiving hoppers of the fine and coarse fraction.

The construction was carried out in the conditions of active production processes.

Warehouse frame hangar on Sakhalin

Warehouse frame hangar on Sakhalin

Bulk warehouse for mineral fertilizers with a capacity of 15 thousand tons

Bulk warehouse for mineral fertilizers with a capacity of 15 thousand tons

Combined warehouse shed

Combined warehouse shed